3 Features.

1

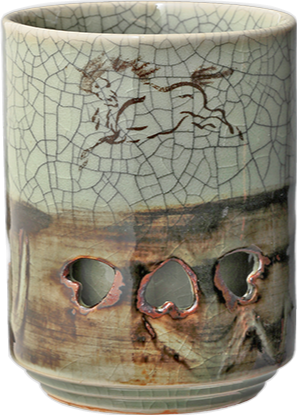

1Depicted horse

The "Sacret Horse" of the Soma Clan at Edo period is depicted, also known as the "Left Horse," meaning "it is second to none." It is known as a sign of good luck in the area. The painting technique used is called "Hashiri Goma," and known as the Kano style like “Kano-Eitoku” . This hand-drawn sacretn Horse of the Soma Clan shows the illustrator's high skill.

2

2Crack

Along with the crazing sound, a pattern of cracks known as "Blue Cracks" is spread across the entire work. The beautiful crazing sound, chosen as one of the "Sounds of Utsukushima 30 Scenes". Because of the different contraction rates between the material and glaze, the pottery develops find cracks across only the surface not into the cray, along with delicate sounds. This is called crazing. This is how the Soma ware are engraved with the pattern called "Blue Cracks."

3

3Double layered

A structure called "Double layered." It allows for hot water to stay hot, but to hold the pot without getting burned when it is very cold like Soma. This technique is unique to Soma ware and is very rare. Originally, Soma ware was used in daily life by the traditional Soma people, and it is said that this technique was born through trial and error to make the containers more useful."

Process

1 Forming

The most important phase of the pottery process is the forming. In Obori-somayaki, potter's wheels are mainly used but on the other hand the moulding is very popular among other pottery.

2 Sculpting

Taking the half-dried product, the decorations such as ""Tobi-kanna"" (dotted patterns) are sculpted, depending on the product.

3 Applying base decoration

Depending on the effect to be achieved, we either take the half-dried product and cut out flower shapes (""Hananuki""), paint clay (""Doronuri""), or press chrysanthemum flowers (""Kikuoshi""), or we take the completely dried product and sculpt.

4 Drying

If the product is dried too quickly, during the contraction process cracks can form or the product can become warped. Therefore, it is dried in the shade before drying under the sun.

5 Bisque firing

The completely dried products are put into a kiln and fired at between 900 and 950 degrees Celsius.

6 Underglaze decoration(Painting)

Using a brush, pictures such as ""Hashirigoma"" running horses, mountain and river landscapes, and pine-bamboo-plum, are painted, using a color called ""Gosu"", which contains metal, usually cobalt.

7 Glazing

Glazing is done by methods such as dipping, pouring in a circular motion, or pouring with a straight motion.

8 Glaze firing

The glazed product is put into a kiln, and fired at between 1250 and 1300 degrees Celsius.

9 Overglaze decoration

Craftmans fire potteries in a kilin at 1250 to 1300 degrees.

10 Inking

In order to display the ""crack"" patterns in the product more distinctly, ink is rubbed into the surface, then removed with a cloth. The product is then complete."

Back to Top